E5x

STATE OF THE ART IN SERVO-ELECTRIC PUNCHING

An early and major step towards sustainable fabrication was taken on the introduction of the servo-electric E series turret punch press in 1998. Now Prima Power offers already the third generation of this series.

The genius of servo electric punching is how it combines energy savings and ergonomics with superb accuracy and productivity. The Ex series has been designed to offer versatile capacity made easy to utilize; Prima Power’s new machine control and user interface software with touch screen panel ensure fast set up and convenient operation. With the Prima Power Ex series, modern servo-electric punching productivity is truly within easy reach.

The servo-mechanically actuated punching stroke is NC-controlled and thus, in addition to high-performance punching, outstandingly accurate forming capacity is available.

Highlights

- Customer oriented puching solution

- Flexible customer-specific turret layout up to 250 tools

- MultiTools® for additional punching versatility

- Rugged “O” frame

- 17/20/23 tons punching force up to 8mm

- Low energy consumption and connection power

- Various automation modules: SU3, LST, Compact Express

- Work chute for max. 500 mm x 500 mm parts

- Programmable clamp setting (PCS)

- Intelligent Stroke Control (ISC)

AUTOMATION:

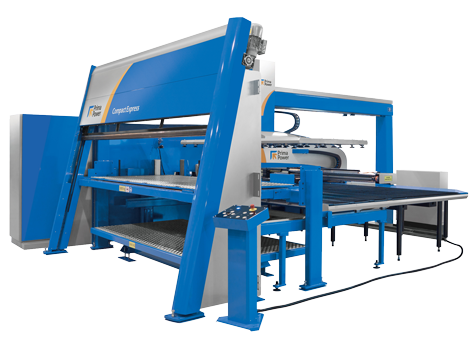

- Compact Express – fast loading and unloading with a small footprint

- LST – compact solution for loading and component sorting

- SU3 – smart sorting solution for small work chute parts

- NT – Connection to Night Train or Combo storage possible when using LST device

High productivity due to versatility, high speeds, ease of operation, minimum set up times

Small power supply connection and very low power consumption

Inherently low maintenance cost

High tooling capacity – fast setup and less waiting time

Brush tables for low noise level and to maintain perfect sheet surface quality.

17/20/23 tons punching force up 8mm = various end user solutions

Individual clamp movement = 100% of sheet utilization

Operations can be handled from one side = simple, efficient factory logistics

Average power consumption: 4 kW = less use of energy

Extremely high servoelectric punching accuracy = less scrap, more production

Fewer critical components compared to hydraulic machines = low maintenance costs

Robust ”O” type frame for perfect tool alignment = less wearing of punching tools

Full 2,5 m working area without repositioning = higher production volume and time savings

Sheet size 1,250 mm x 2,500 mm without repositioning

Punching speed up to 700 hpm / 1 mm between holes

Punching forces 17, 20 or 23 ton (19.1, 22 or 25.3 US ton)

Tool rotation speed 133 rpm