LHF-506E

HYDRAULIC INITIAL-PINCH PLATE ROLLS

The Hydraulic Initial-Pinch Plate Rolls is designed for job-shop fabricator. It is simple to operate while producing high quality results. The machine is using high quality steel welded to a structural steel frame for rigidity. All rolls are hardened at least to 50 Rc to reduce scratching and pitting and are journalled in high-quality roller bearings to provide longer life. The top and lower rolls are driven by a high efficiency motor with built-in braking for getting high performance and result. The hydraulic system and cylinders provide the power to adjust the lower (pinch) and rear (bending) rolls as well as the drop end for easy removal of the finished cylinder. Controls on this machine is conveniently located and easy to use via the integrated console with all pushbuttons for all function and a standard LED readout provides fast and easy positioning of the rear bending roll for repetitive work. A unique design on this machine is “Pinch Gauging Device” for added efficiency and to eliminate the guesswork of pinching pressure. This helps insure excellent repeatability. The optional device on this machine is a set of hardened cone bending device for cone bending job. The other is cable type emergency stop device for more safety requested. The working capacity range is suitable from 3mm – 16mm thickness by 900mm – 3000mm width. Rolls diameter is between 80mm and 240mm. Its production range is right just cover the most vast range of requirement in the market.

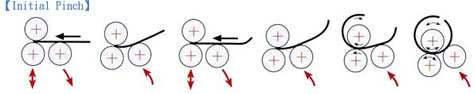

Rolling Flow Chart

Standard Equipment

- Rolls made of forging steel, and thru high frequency heat treatment at HRC45°.

- Hydraulically powered lower pinch roll adjustment, with rapid gap adjustment.

- Hydraulically powered rear bending roll adjustment.

- Hydraulically powered tilting of the rear bending roll for cone rolling.

- Simple manual tilt of the lower pinch roll.

- Spherical roller bearings on all roll shafts.

- Pinch gauge device.

- Electronic digital LED readout for rear bending roll position.

- Hydraulic drop end.

- Dual rotation controls – console mounted and remote foot switch on trailing lead.

- Tool box and operation manual.

Optional Equipment

- Cone bending attachment

- Emergency stop cable at front and rear of machine