Explorer 1 Drilling Center

Explorer 1 Drilling Center

Description

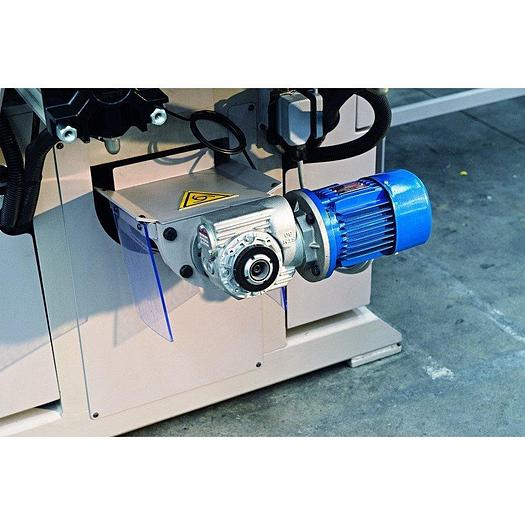

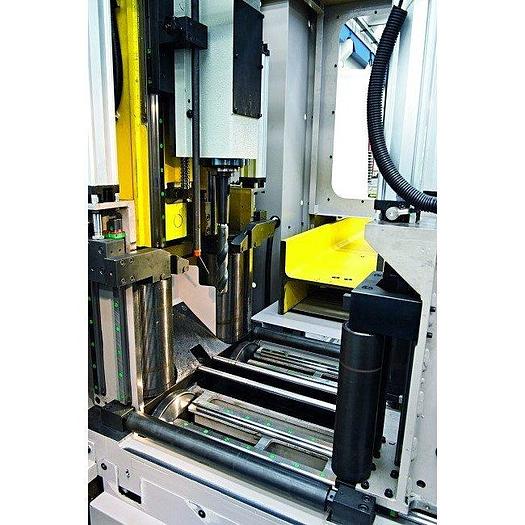

Ideal for Applications in the Following Industries: Architectural metal Boat Manufacturers Fastener and Bolt Manufacturers Machine Shops Metal Fabricators Ornamental Iron and Railing Shops Steel Service Centers Stainless Steel Fabricators Steel Service Centers Structural Steel Fabricators Trailer Manufacturers Tube and Steel Suppliers Standard Features & Equipment: 3-Axis CNC Vertical Drilling Center Capable of Drilling, Slotting, Milling, and Tapping Y-Axis and Z-Axis Positioning is Servo Controlled with a Ball Screw X-Axis Positioning is Servo Controlled with FMB’s Rotary Automatic Material Indexing System Allows for pieces up to 98ft to be indexed in a single movement Work up to 98ft long pieces from End to End 15" Color Touchscreen Control is very Intuitive so Machine Programming is easy and simple Material Table – Easy Selection of Part Dimensions Tool Table – Create and Save Tools Part Measurement System When a part is loaded into the Explorer 1, it uses a laser to find the incoming edge of the part. It then measures the height and width of the loaded piece to confirm the actual part dimensions match the programmed dimensions. Mist Lubrication System includes through tool coolant Remote/Offline Programming is Available Technical Specifications: Max Incoming Part Length – X-Axis 98ft Y-Axis Travel 16-1/2" Z-Axis Travel 25-1/2" Max Part Width 17-3/4" Min Part Width 1-1/2" Max Part Height 11-7/8" Min Part Height 3/8" Max Drilling Diameter 1-1/4" Min Drilling Diameter 1/5" X-Axis and Y-Axis Positioning Speed 30 ft/min X-Axis (material indexing speed) 18 ft/min Max Spindle Speed 3,000 RPM Spindle Power 8.25 HP Tool Holder ISO 40

Specifications

| Manufacturer | Pat Mooney Saws |

| Condition | New |