OCEAN LIBERATOR CNC BEAM COPING MACHINE

OCEAN LIBERATOR CNC BEAM COPING MACHINE

Description

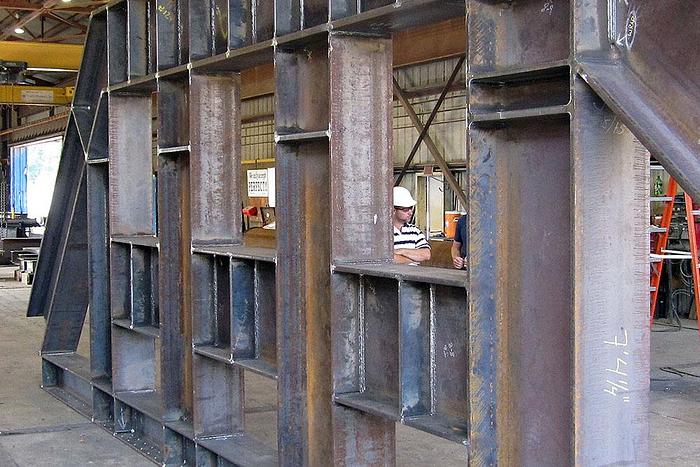

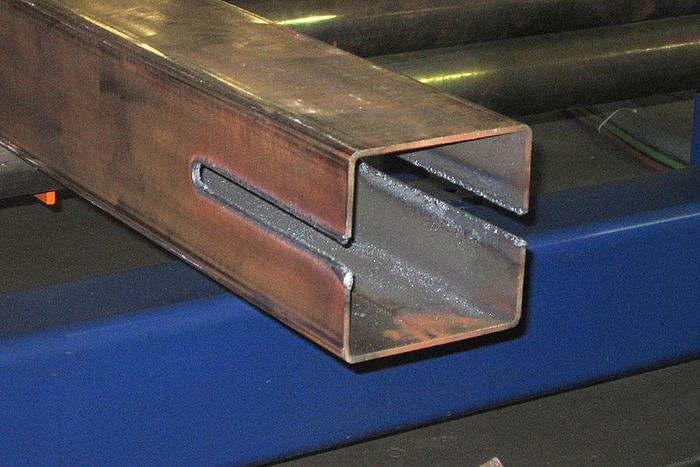

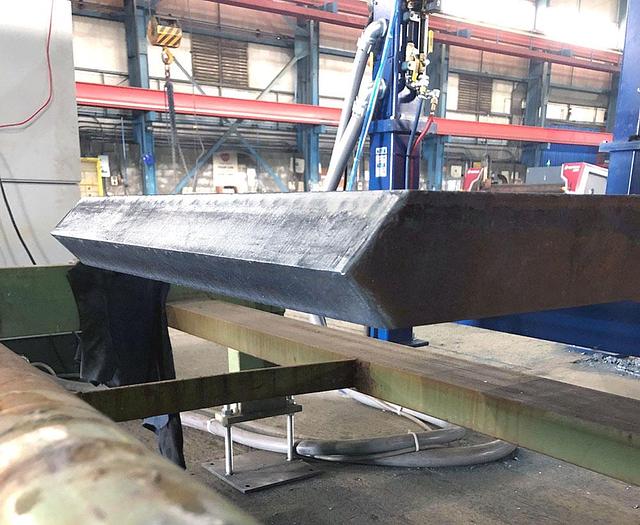

The Ocean Liberator features a rigid heavy duty frame welded frame that easily mates to a variety of automatic or manual in-feed and out-feed conveyors (typical configuration uses 45ft of in-feed and 45ft of out-feed conveyor). This solid frame provides the rigid platform from which the articulated 5-axis torch is driven, ensuring accurate and repeatable copes and cuts in a variety of profiles. The Liberator uses a 5-axis fully articulated cutting torch, which allows it to cut from any angle on any surface, easily allowing bevel cuts in both the web and the flanges, something that more expensive multi-head machines are unable to do. The beam coper is equipped with a heavy-duty automatic igniter for simple automatic ignition. A handheld remote pendant allows fine-tuning of the cutting gap and travel speed, and provides the operator freedom of movement during cutting. This supremely versatile machine allows coping and cutting of beams, channel, angle, plate, tube. The Liberator cuts steel at speeds of up to 30 inches per minute depending on material thickness and hardness, type of gas, flame adjustments, and other factors, and has a fast positioning speed of up to 400 inches per minute. Simple and easy to operate. No computer experience required. Fastest Return on Investment of all Ocean products. Immediate payback on a low investment through attractive finance options Travel Speeds Cutting with Oxyfuel +/- 0.0625″ (1.5mm)

Specifications

| Manufacturer | Ocean Machinery |

| Condition | New |

| Maximum Profile Size | 44″ x 24″ (1100mm x 600mm) |

| Maximum Plate Width | 48″ (1250mm) |

| Flange Bevels | +/- 45 degrees |

| Web bevels | +/- 45 degrees (external only) |

| Maximum Material Thickness | 6″ (150mm) |

| Type of Cuts Programmed | All cuts are programmable |

| Traverse Speed | 100 – 400 in/min (2.5 – 10m/min) |

| Cutting Speed | 7 – 30 in/min (170mm – 750mm/min) |

| “X”-axis | (direction of flow) 46″ (1168mm) |

| “Y”-axis | (cross travel) 76″ (1930mm) |

| “Z”-axis | (vertical travel) 30″ (762mm) |

| “B”-axis | (bevel angle) 270 degrees |

| “C”-axis | (torch rotation) 270 degrees |

| Repeatability of X, Y & Z | +/- 0.001″ (0.025mm) |