Coil Handling & Press Feed Lines

Coil Handling & Press Feed Lines

Description

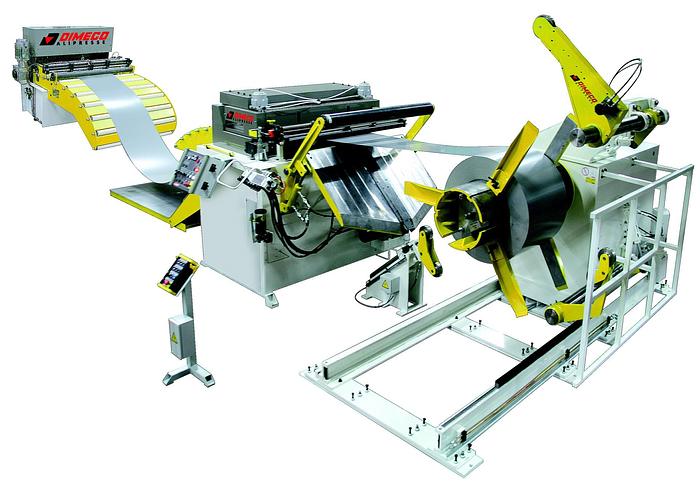

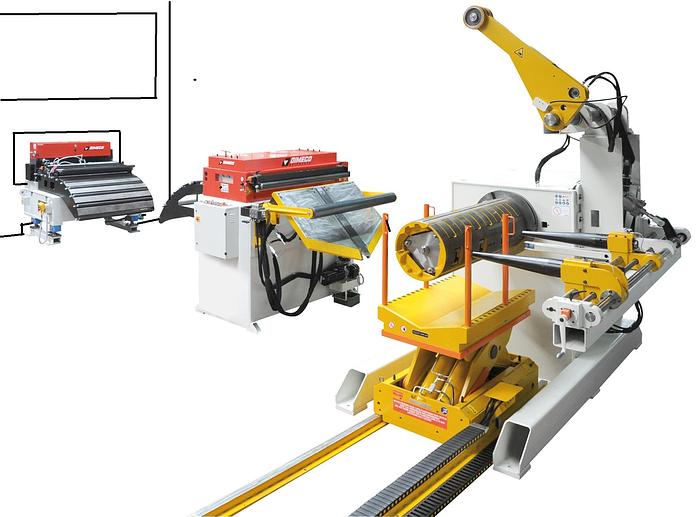

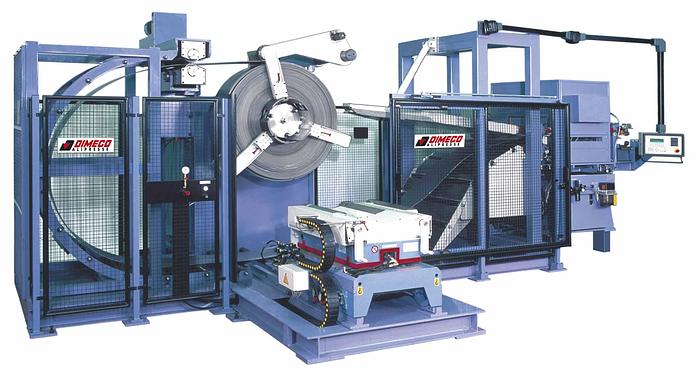

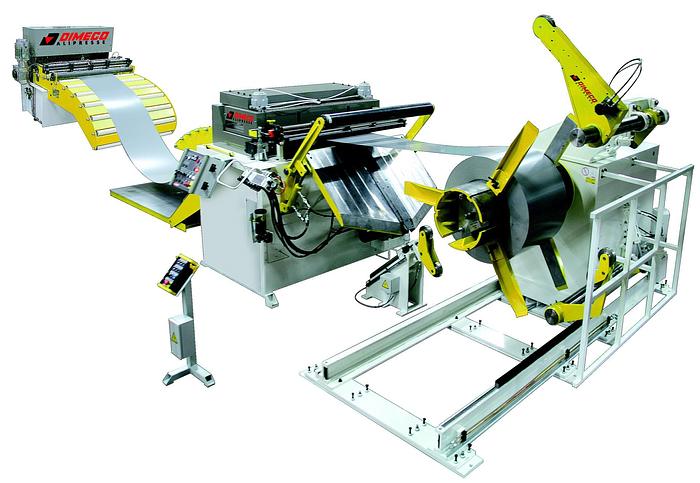

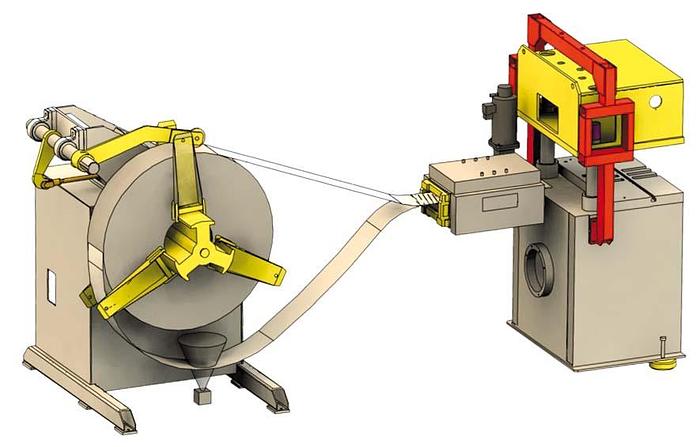

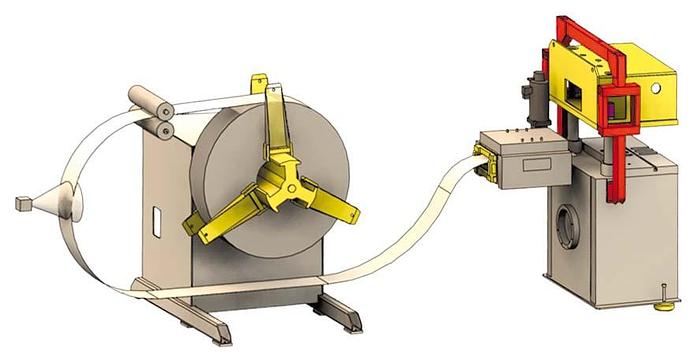

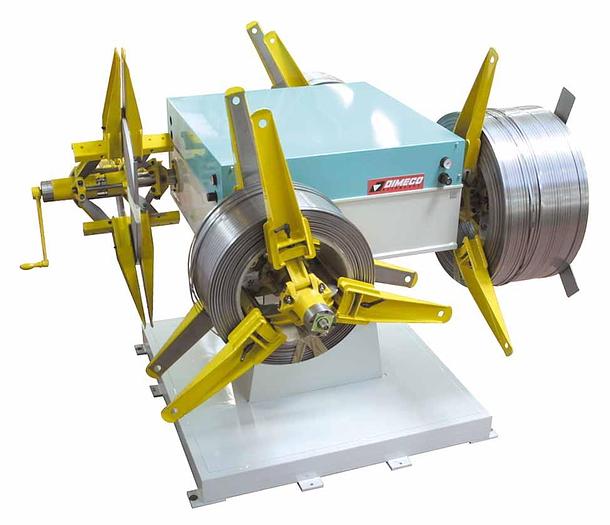

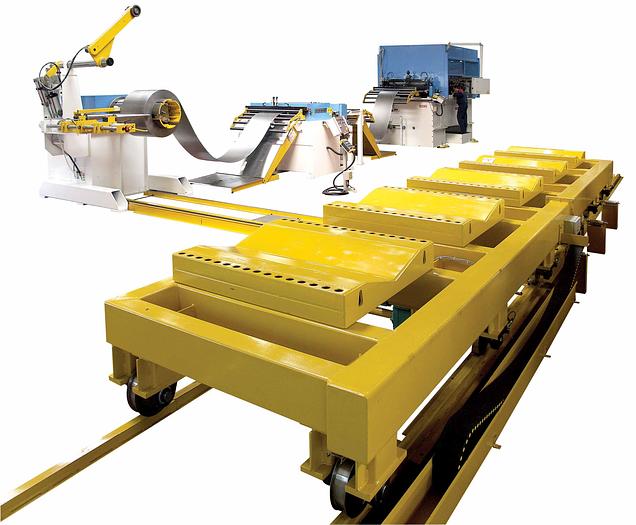

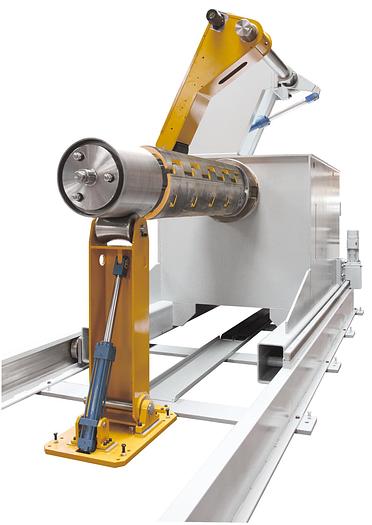

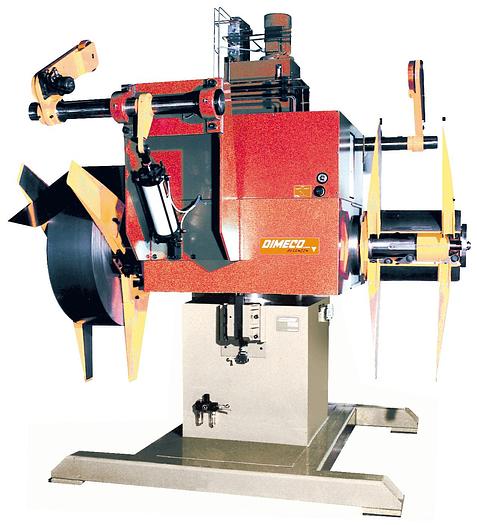

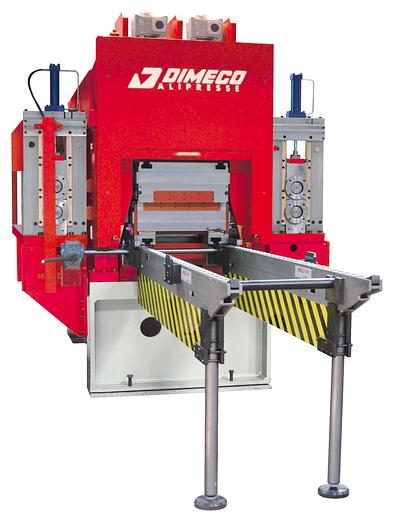

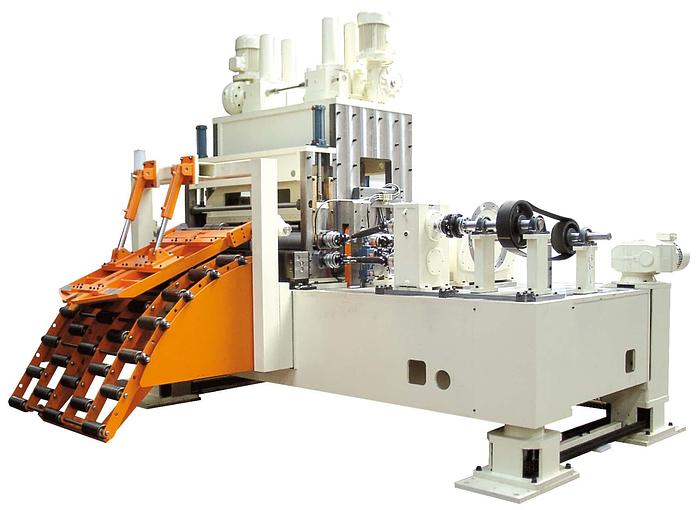

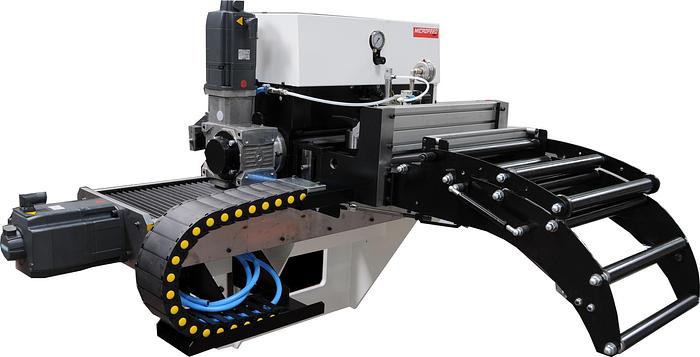

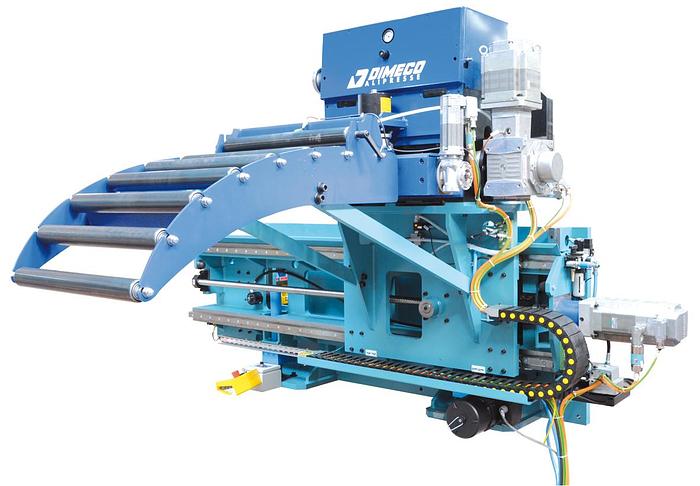

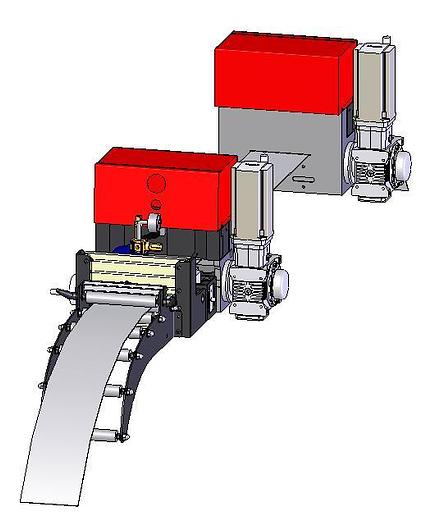

55 years of continuous coil line technology development has elected Dimeco as one of the world biggest supplier to the stamping market as well as to fabricating. Dimeco provides the world widest range of equipment, matching needs of small press shops up to major automotive market players. Huge R&D work has been achieved to develop the new levelling technologies required by the evolution of materials available today (high press steel). Main features of equipment: Coil weight from 200 kg (440 Lbs) to 35 tons (77,000 Lbs) Strip width from 200 mm (8”) to 2000 mm (79 “) Material thickness from 0.1 mm (4 thou) up to 10 mm (0.4 in.) Material quality from soft aluminium up to 1500 Mpa high press steel Coil cradle, 3 in 1 combination, short line & long line configurations match all applications. 55 years of continuous coil line technology development has elected Dimeco as one of the world biggest supplier to the stamping market as well as to fabricating. Dimeco provides the world widest range of equipment, matching needs of small press shops up to major automotive market players. Huge R&D work has been achieved to develop the new levelling technologies required by the evolution of materials available today (high press steel). Main features of equipment Coil weight from 200 kg (440 Lbs) to 35 tons (77,000 Lbs) Strip width from 200 mm (8”) to 2000 mm (79 “) Material thickness from 0.1 mm (4 thou) up to 10 mm (0.4 in.) Material quality from soft aluminium up to 1500 Mpa high press steel Coil cradle, 3 in 1 combination, short line & long line configurations match all applications. KONICA MINOLTA DIGITAL CAMERA 10 11 < > Download PDF Brochure Line Structure Long lines The most efficient, the fastest, the one to use with delicate materials. Straightener and feeders are separated by a loop allowing the feeder and the press to run at maxi speed with a smooth and continuous process in the straightener. Speed software automatically matches feeders and coil unwinding speed together with press rate and feed length. Infeed peeler & table allow safe and quick coil change process. < > Short lines How to save space… The best for heavy materials… Straightening and feeding operations are combined in one machine. We use either a loop under coil or a rear loop when possible. For specific applications, a servo driven uncoiler is used to match feed rate. < > Quick Coil change Today challenge is to make short runs and to get the press running as much as possible… Solutions for quick coil change: Double and quadruple uncoilers Integrated coil loading (tilting) equipment Multiple coil holder Autonomous coil loading & tilting car KONICA MINOLTA DIGITAL CAMERA < > Operator safety New stronger materials bring risks which must be overcome by specific ancillaries. Coil containing snuber rolls Infeed peeler Threading table Perimetre fencing with safety locks and light barriers < > World widest uncoiler Range KONICA MINOLTA DIGITAL CAMERA 10 < > Model Metric US Weight (kg) Width (mm) Weight (lbs) Width (inches) Up to Up to Up to Up to 2310 200 200 440 Single & Double 2330 500 300 1,100 12 Single & Double 2350 1,000 500 2,200 20 Single & Double 2371 3,000 800 6,600 31 Single & Double 2381 4,500 800 9,900 31 Single & Double 2384 6,000 1300 13,200 51 Single & Double 2386 8,000 1300 17,600 51 Single Only 2387 10,000 1500 22,000 59 Single Only 2395 15,000 1800 33,000 71 Single & Double 2398 25,000 2000 55,000 79 Single Only 2399 35,000 2000 77,000 79 Single Only Straightener & corrective leveller range KONICA MINOLTA DIGITAL CAMERA < > CRADLE TYPE STRAIGHTENER Model Metric US Width (mm) Thickness (mm) Width (inches) Thickness (inches) Up to From Up to Up to From Up to 1632 100 0.1 0.004 0.039 1633 160 0.2 0.008 0.079 1634 665 0.2 3.5 26 0.008 0.138 1681 410 0.2 2.5 16 0.008 0.098 1683 1,825 0.2 3.4 72 0.008 0.134 1684 2,050 0.3 81 0.012 0.236 1685 2,050 0.4 81 0.016 0.276 INDIVIDUAL ROLL ADJUSTMENT STRAIGHTENER Model Metric US Width (mm) Thickness (mm) Width (inches) Thickness (inches) Up to From Up to Up to From Up to 1635 300 0.4 12 0.016 0.039 1645 500 0.2 20 0.008 0.118 R674 1,300 0.15 51 0.006 0.157 R676 1,300 0.4 51 0.016 0.236 R690 2,000 0.5 79 0.02 0.315 R691 2,050 1.2 81 0.047 0.354 R6925 2,050 0.15 5.5 81 0.006 0.217 CORRECTIVE LEVELLERS Model Metric US Width (mm) Thickness (mm) Width (inches) Thickness (inches) Up to From Up to Up to From Up to P693/6 2,000 0.2 79 0.008 0.079 P694/6 2,000 0.3 2.5 79 0.012 0.098 P696/6 2,000 0.6 4.5 79 0.024 0.0177 P697/6 2,000 1.2 79 0.047 0.0236 Servo Feed range KONICA MINOLTA DIGITAL CAMERA < > Model Metric US Width (mm) Thickness (mm) Width (inches) Thickness (inches) Up to From Up to Up to From Up to 1050 105 0.2 0.008 0.039 1060 310 0.2 1.5 12 0.008 0.059 1082 815 0.2 32 0.008 0.118 1100 1,020 0.2 40 0.008 0.236 1125 1,500 0.2 6.35 59 0.008 0.25 1160 2,050 0.2 10 81 0.008 0.394 Straightener feeders are available within same range as straighteners Staggered and push pull feed All feeders and straightener feeders can be implemented with “Zig Zag” base allowing staggered stamping. Push pull feeders with synchronized servo controls are also available. < > Request info Request More Info Your Name (required) Company (required) Country (required) Your Email (required) Subject Your Message Part drawing: I have read and I accept the Terms of Use and the Privacy Policy .

Specifications

| Manufacturer | Dimeco |

| Condition | New |