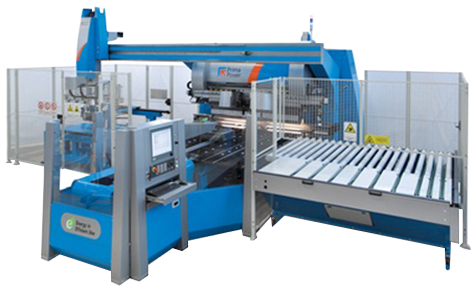

Express Bender – EBe

A NEW SOLUTION FOR HIGH-QUALITY BENDING

Well known for advanced bending technology and innovative servo-electric applications, Prima Power has combined them in the new automatic bending cell EBe. EBe automates the bending process of high-quality sheet metal components.

Compared with all-hydraulic solutions, truly remarkable savings can be made in your component manufacturing.

The new construction features actuation of the bending blade movements (vertical and horizontal) by servo NC-axes instead of hydraulic cylinders. The upper tool movements are made also by another NC servo-axis.

Prima Power EBe provides the high bending quality required in demanding applications such as component production for design products. This is achieved through precise control of bending axes, fast and smooth bending, open programmability, and the fact that the construction is immune to variation in thermal conditions.

Highlights

- Servo-electric technology: very low energy and maintenance costs, reduced impact on manufacturing environment (minimum noise and vibrations), no influence of thermal conditions, and excellent component quality

- Fully automatic loading and unloading operation

- Loading device with automatically adjustable gripper and loading table with double sheet detector

- Unloading table with free rolls allowing the operator to remove the finished components from the safety area

- Two bending principles: rolling mode (wider contact surface between the blade and the sheet but no relative friction) and circular mode (same contact point on the panel, while the one on the blade changes during bending movement)

- Sophisticated software, including graphic parametric programming, and simulation at operator interface

- Off-line programming

- Configurability with all Prima Power bending options

- Upper pressure force automatically adjusted according to the material thickness and length

- Aautomatic recording of bending parameters in material data base

Efficiency Fully automatic loading and unloading operation suitable for medium to long series manufacturing

Quality Excellent bending quality as required by e.g. design products

Cost effectiveness Low overall operation cost due to low energy consumption (-64%), low oil maintenance cost, very fast operation

Low energy consumption (-64%) – less CO2

Very low noise level

Reduced vibration

Carefully thought ergonomics through integrated safety covers

Max bending length EBe4 2,250 mm – EBe5 2,650 mm – EBe6 3,350 mm

Min length between bends (*) EBe4, EBe5, EBe6 350 mm

Min width between bends (*) EBe4, EBe5, EBe6 160 mm

Bending force EBe4 32 tons – EBe5 (2/3) 30/41 tons – EBe6 41 tons

(*) these values cannot coexist in a single construction