STANDARD FEATURES

|

|

|

|

|

|

| Large Vee-notcher (punch side) |

Channel Shear | Pipe Notcher | Single Vee Press Brake |

Multi Vee Press Brake |

Large Hole Punching |

|

|||||

| Goose-neck Die Holder for Punching Channel Flanges and Webs |

SPECIFICATIONS

Punching Pressure 85 Ton

Punch Capacity ø27 x 22

(Diameter x Thickness) ø50 x 12

Throat Depth 410

Channel Flange Punch 75-180

Max. Stroke Length 100

Cycles / Min. (15mm stroke) 38

Working Height Up to Die 1050

Punch Capacity ø27 x 22

(Diameter x Thickness) ø50 x 12

Throat Depth 410

Channel Flange Punch 75-180

Max. Stroke Length 100

Cycles / Min. (15mm stroke) 38

Working Height Up to Die 1050

Flat Bar Shearing 406 x 17

Blade Length 410

Working Height 726

Blade Length 410

Working Height 726

Shearing Capacity 110 Ton

Shearing Cylinder Stroke Length 50

At 90° Shearing 130 x 130 x 12

Working Height 1040

Shearing Cylinder Stroke Length 50

At 90° Shearing 130 x 130 x 12

Working Height 1040

Round Bar Shear ø45

Square Bar Shear 45 x 45

Channel Shear 152*

I Beam Shear 152*

Square Bar Shear 45 x 45

Channel Shear 152*

I Beam Shear 152*

Rectangular Notcher (W x D xT) 63.5 x 90 x 12

Vee-Notcher (Side x Side x T) 105 x 105 x 12*

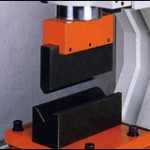

Large Vee-Notcher (Side x Side x T) 145 x 145 x 10*

Channel Notching 180-200

Working Height 1050

Vee-Notcher (Side x Side x T) 105 x 105 x 12*

Large Vee-Notcher (Side x Side x T) 145 x 145 x 10*

Channel Notching 180-200

Working Height 1050

Single Vee Press Brake (W x T) 250 x 15*

Multi Vee Press Brake (W x T) 500 x 5*

Angle Bending 102 x 8*

Pipe Notching ø100*

Multi Vee Press Brake (W x T) 500 x 5*

Angle Bending 102 x 8*

Pipe Notching ø100*

Electric Power (HP) 10 HP

Net Weight (Apr.) 2750 kg

Gross Weight (Apr.) 2900 kg

Machine Dimension (Apr.) 1795 x 1020 x 1865

Packing Dimension (Apr.) 2150 x 1180 x 2170

Net Weight (Apr.) 2750 kg

Gross Weight (Apr.) 2900 kg

Machine Dimension (Apr.) 1795 x 1020 x 1865

Packing Dimension (Apr.) 2150 x 1180 x 2170

Unit: mm

*optional tooling.

Based on material strength of 45kg/mm2 tensile.

Design and specifications subject to change without notice.